Melanie Prince, head of innovation at F/List, outlines some key interior design trends for the business jet sector

Surface materials

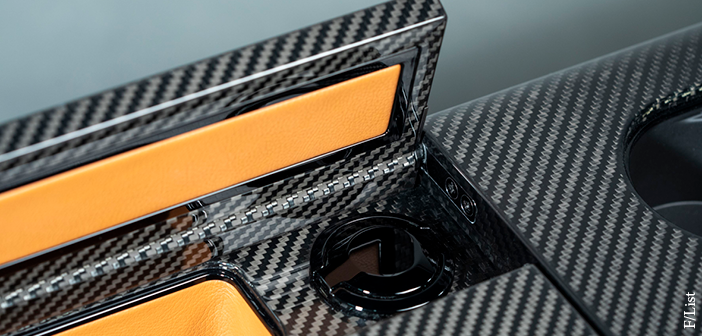

The use of decorative carbon fibre is increasing. The iridescent characteristics of carbon fibre make it a modern surface material for monuments and accents.

The ability to add new surface materials to components is also trending and customers are more interested in stone, wood and other natural material finishes. We have added ceramics, real glass and genuine metal finishes to our options for surface finishes. We are seeing more requests for glass surfaces, including mirrored options and seamless metal inlays, which enable a plethora of design options.

There’s also an increasing demand from our customers for eco-friendly materials. We have been working with materials that contribute to the preservation of rainforests, for example we will integrate fair-trade materials that foster local farming communities.

Colour, pattern and texture

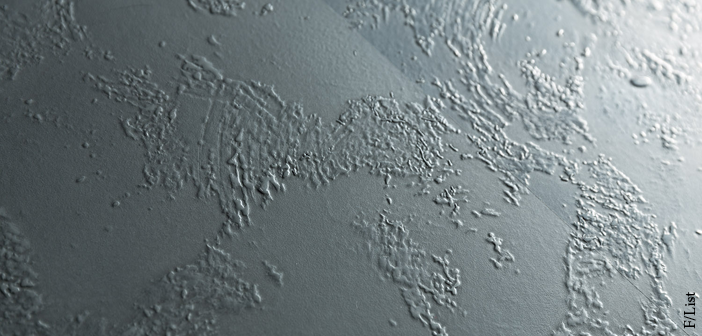

There is a definite trend for customers asking for natural environments, organic shapes and complementing this with natural products in the cabin. We’re seeing a much greater use of natural stone effects, wood veneers in new locations, for example on the bulkhead, as well as an increase in smooth surfaces like glass finishes. Mirrored bulkheads, glass table surfaces and underlit stone surfaces are all trending. In response to raised demand for organic shapes in the aircraft we have created Fresco Décor, which offers a wide range of embossed three-dimensional surface options and can be used on a wide variety of monuments including bulkheads.

The desire for eco-friendly and natural surfaces is popular and in response we’ve created a rattan surface product. It is a natural material derived from a vine. The product is sustainable and has exciting stain and finishing options.

We are developing a fully organic certified leather that is made from agricultural by-products. It looks beautiful and feels completely natural.

Weight

The trend for reducing airframe weight remains a prime consideration and we are regularly asked about how to reduce weight. F/List, together with its joint venture Hilitech, is optimising the benefits of composites and integrating their strength and lightness to create interior components that can reduce weight by up to 30%, while retaining the high quality, functionality and design we are known for. The ability to create products that are feather-light provides multiple options for creating new cabin components without adding significant weight to the airframe. Some of these materials are transferring from the motorsport industry where weight is also a factor in design.

Lighting

Light can affect mood and consequently as we are all becoming more aware of our wellness and health, lighting that emulates circadian rhythms or that positively affects wellbeing in the cabin is a major trend.

Subtle lighting that adds a layered effect to the cabin is something more and more customers are requesting as the aircraft becomes a multipurpose environment delivering work, living and relaxation spaces. In response to this trend, we have created and launched our Illuminated Surface lighting system. This is an easily controlled LED light system that sits beneath very thin stone veneers to create subtle, illuminated surface lighting for a variety of cabin surfaces, including galley and washroom countertops. It adds a different dimension to the overhead or sideledge task-based lighting.

This complements the trend towards lighting areas of the cabin that would normally stay dark, which again expands the feel of the cabin. Subtle lighting in galleys or washrooms delivers an illusion of space.

Cabin operation and HMI

The use of personal digital devices to manage the cabin environment is a growing trend. Once purely the domain of the cabin crew, ambient lighting, temperature, music and the general cabin environment are now in the hands of the passengers. As we continue developing products, we are ensuring that they can be controlled by the passenger, not just cabin crew. For example, our illuminated surfaces can be controlled via a passenger’s digital device.

Customers are also looking for systems that amplify the cabin space and we are responding to these future needs by working on a new product portfolio that enlarges the potential for the creation of multifunctional spaces. The driving force behind our most ambitious ideas is our incubator facility, The F/List Futurelab.

Hygiene

The ongoing pandemic has driven requests for protective products. F/List launched its MicroShield 360 treatment service for finished cabin surfaces in mid-2020. The protective coating, which is applied annually, defends against SARS-CoV-2 and many other pathogens. The system is available for all aircraft types.

Sustainability

Sustainability has become more mainstream as consumer awareness is evolving. It is not just the new, younger owners that are interested in the options, but also the market as a whole – from individual customers through to the OEMs.

Interest in environmentally friendly products that can be incorporated into the cabin is definitely growing. Pressure is growing across the sector, and we see that the ability to support sustainable requests is becoming part of the competitive landscape.

For us sustainability is now a core value, it is part of our corporate strategy, and we already have a number of sustainable production processes in place. Our customers appreciate this too.

We have also been optimising plant residual elements from agriculture to convert them into surface materials, for example precious, decorative materials from fruit by-products, or surfaces made from by-products of our stone machining department.

Further discussion of interior design trends, from designers and completions experts across North America, will be featured in the September 2021 issue of Business Jet Interiors International.