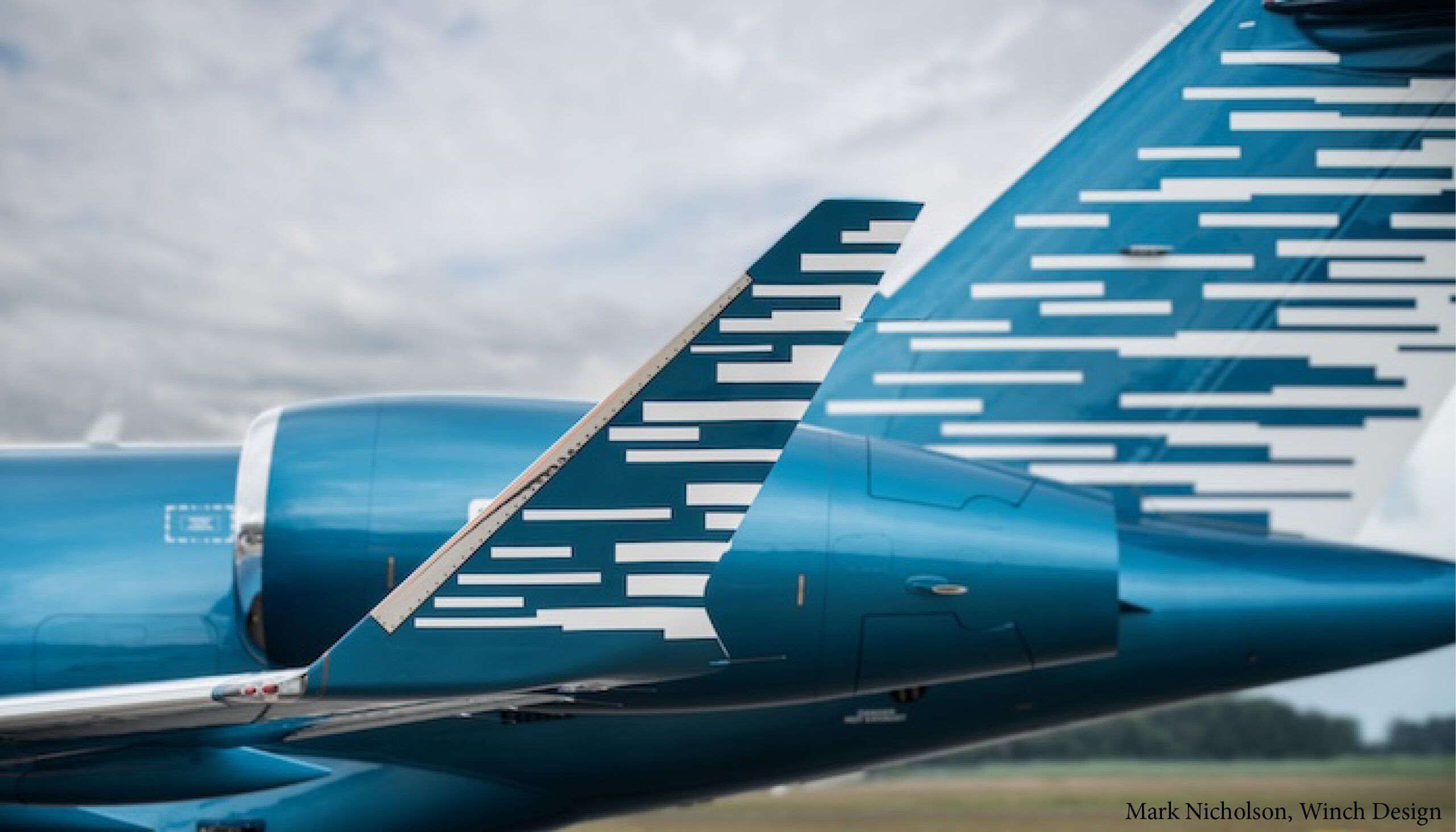

AllianceJet’s refurbished Global 6000 made waves at EBACE, with a sand-and-sea-inspired interior designed by Winch Design and featuring new developments from F/List.

Drawing admirers on static display at EBACE this year, AllianceJet’s newly refurbished Bombardier Global 6000 stands out on the ramp with its teal blue livery, with more details to delight inside.

The Ireland-based charter operator recently took advantage of the aircraft’s 10-year C-Check to update the exterior and interior at Bombardier’s service centre at London Biggin Hill Airport in the UK. “The previous cabin was in very good condition, but somewhat dated in its design style,” says Jim Dixon, managing partner and creative director for yachts and aviation at Winch Design, which created the new design. “The client wanted to really make this a calm interior where you can de-stress, so it was all about making something calm and gentle and emphasising the space.”

Concurrent work

Working within the maintenance downtime was important. During a C-Check, the interior and livery must be stripped to inspect the fuselage and bulkheads – so it’s a great time for upgrades. The layout was kept the same to keep costs in check. “The owner had no particular reason to change the layout, which would mean re-certification,” says Dixon.

From forward to aft, the aircraft features a galley, crew seat and lavatory; four club seats; a dining cluster and credenza; a private aft lounge with a divan that converts to a sleeping space; and private bathroom. “It’s a proven layout that works very well for charter, for 12 passengers maximum,” says Dixon.

The team

The design process took three months, the preparation took a year and the refit three months. Bombardier took care of the maintenance, and the removal and reinstallation of the cabin. F/List was tasked with refurbishing the cabin elements. The forward area cabinetry, carpets and cockpit seats were handled at F/List’s operation at the Bombardier hangar; the rest of the cabinetry was sent to F/List’s headquarters in Austria; while the seats and divan were sent to one of its facilities in Germany.

Markus Schröcker, manager of sales and business development, aftermarket OEM, at F/List, explains that having an on-site team at Bombardier’s hangar, and Winch Design nearby, was a big help. “It was such a smooth process,” he says. “We have a team on-site that could always provide support.”

Durability and ease of maintenance were key requirements, given the jet’s busy charter remit. To this end, the team opted against replacing the cabinetry veneer, instead applying a foil wrap, an imitation of straight-grain walnut.

Foil wrapping

Schröcker says foil wrapping is particularly popular for charter aircraft, and estimates it features on more than 50 aviation projects F/List has worked on. He says the benefits include a swifter turnaround, cost savings, colour consistency, and repairability in service.

It is also useful on projects such as this where there is a shift from dark to light tones. “Previously if you wanted to go from a dark brown veneer to something light in colour, the only option was to strip the old veneer and apply the new one,” says Schröcker.

Additionally, if going the staining route, this would only work if going darker in tone. “With foil wrapping, the old veneer stays underneath and you just apply the foil over it,” he adds. “You can go from dark to light in a more cost-effective way.”

In-service repairs

Schröcker explains that if damaged in service, foil wrap can be replaced simply, sometimes without having to uninstall the component. On the other hand, replacing wood veneer involves removing the component, sanding, re-varnishing, polishing and reinstallation.

“Even during a refurbishment, using foil wrap reduces downtime,” he elaborates. “Versus a re-veneer you’re cutting time in half. You also don’t get the ageing effects of a classic wood veneer.”

Schröcker says foil wrapping is growing in stature as a solution. “For a prestige design company like Winch Design to select a foil finish was to me an honour towards this technology, because it’s finally acceptable also for high-end projects,” he says.

“The foil wrap technology we use is much, much better than it used to be a few years ago,” explains Dixon. “Foil wraps have an authenticity now, a tactility as well as a very good visual quality that makes them – to the naked eye – very, very close to a natural veneer material and so much quicker and cheaper to apply than re-veneering.”

Slatted screens

The team came up with special solutions for the bulkheads. The forward and middle bulkheads have a 3D slatted effect, resembling Japanese shoji screens. They are made from vertically aligned, foil-wrapped wooden-look slats, with Lexan mirror placed in-between to give the illusion of seeing through.

“As always, we’re trying to emphasise long sightlines through the plane, and key to that was the treatment of the bulkheads,” says Dixon. “Previously they were typical solid bulkheads with sliding doors.”

The sliding doors are retained. Other practical challenges resulting from the bulkhead changes included needing to reposition switches and exit signs, and ensure the internal valance panel was still able to hinge down for maintenance. Dixon says the biggest limitation with the slatted design was weight. “We had to ensure the weight of the new elements was still within the certification envelope,” he adds. “That required us to tweak and refine and develop those elements alongside F/List.”

The slatted screens are Schröcker’s favourite element of the project; he had only seen similar ideas in renderings previously. Bombardier supported the F/List team in defining a framework for certification limits as to weight, stress and so on, Schröcker says. “It then became simpler than we thought,” he continues. “Winch designed the slats and none are identical to another. They are each a single slat, and this is a 3D engineered piece, which we milled in-house. Then they were foil wrapped and you’ve got the mirrors in between.”

Burl wood marquetry

To avoid overdoing the slatted effect, the aft lounge bulkhead is decorated with marquetry made from real walnut burl wood veneer. Irregular pieces are brought together like a jigsaw. “It’s just one material, but set with the grain orientation in different directions to give it dynamism,” says Dixon.

F/List implemented it using in-house veneer, topped off with a new development by its F/Lab – an oil finish designed to give an open-grain look while being scratch- and stain-resistant. “It’s a great new addition to the market,” says Schröcker. “Rather than having a thicker layer of clear coat or varnish, you really sense the nature of the veneer.”

The oil wood finish is now an option for serial production, cleared for aviation. To counter the lack of UV-filtering varnish, the F/Lab developed a modification of the wood veneer and the oil finish to resist UV discolouration. For mechanical resistance to wear and scratches, the oil finish is chemically cured. The oil finish is based on natural raw materials. F/List also developed cleaning, maintenance and repair procedures for it.

The headliner and walls were also resurfaced with a new F/Lab development – Fresco engineered leather. “We included a very subtle, very gentle wave pattern, which gives it a 3D quality and is picked up by the recessed lighting in the PCU panel,” Dixon says.

F/List did several iterations of samples to bring the vision to life. Schröcker says having the team from Winch Design on-site so often made it easier, but this was probably the most challenging element.

Remodelled seating

The seats were remodelled in F/List’s upholstery shop in Berlin. Schröcker describes the design as “super complex” with lots of details. The Winch Design team visited the shop to help develop the first prototype. Aeristo supplied all the seat leather. The focal point is an embossed and stitched centre backrest panel. “Aeristo are experts in providing different designs of embossed and perforated stitched leather that look wonderful,” says Dixon. “We’ve used that in combination with a plain full grain and on the outside of the arms a very hard-wearing fabric. We’re cognizant of people brushing up against the sides.”

The hand-tufted wool carpet by Tai Ping brings it all together, also referencing the livery. The design was inspired by the beach and ocean. “It has this wonderful and organic wave of blue and cream in combination, which was then picked up in the accessorising combination,” explains Dixon.

The blue colour is also echoed in stitching around the leather inlays on the tables – one of many details that give the aircraft a custom look. For Dixon, it is the jet’s bespoke, leisurely feel that is the most satisfying element. “We’ve transformed it from the original,” he says. “This interior is about relaxation. We’re always trying to create a feeling of space and comfort.”

This feature was written by Izzy Kington and first published in the July 2024 edition of Business Jet Interiors International. Click here for the full version.