Larry Ayres shares how he came to be a mock-up builder at Textron Aviation

How did you get into this craft?

I had been working for a custom van company for more than 10 years. A friend who retired from Cessna encouraged me to apply. Outfitting interiors is a specialised skill and there isn’t a lot of turnover, so it took several months before I received a phone call.

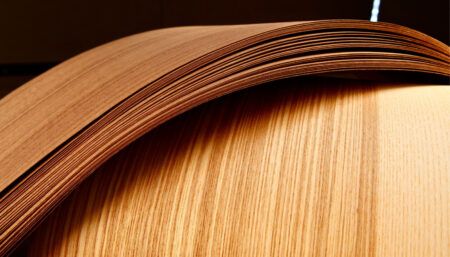

I began working in the cabin completion centre in 1991. I really liked working on my own and decided to move to cockpits; I built all Citation cockpits for the next eight to nine years. In my spare time, I make guitars and mandolins, and build cars. I once brought in some of my mandolins, and the styling centre supervisor saw them, which led to a new opportunity. The styling centre builds mock-ups and other development articles and he asked if I would help out with some of their cockpits. I started helping out when needed and eventually moved to building mock-ups and prototypes full time. I have been doing this for 19 years.

What do you love about it?

I work on different projects every day and use different skills like welding steel and aluminium, riveting, working with composites and wood, and building tooling for vacuum-form machines. By far the best part of this career is the variety. I also like working with my hands and creating things from nothing.

What are the challenges?

Completing projects in a timely fashion can be challenging, but it’s rewarding to know I’m involved in providing the solution. The pace requires creativity – you need to figure out how to construct what is needed.

Every day presents a different problem to be solved, which results in a different solution. I am surrounded by talented and motivated people – designers, engineers and craftspeople – and we turn new ideas or technologies into reality every day.

What are you most proud of?

I like a challenge and it is very gratifying when I am asked to build something others cannot. Also, I worked on an idea that has been submitted for a patent. On another project, I worked on a new method of cockpit trim installation that allowed us to hide the screws.

I am also very proud of the Pro Street Datsun 280Z I built from the ground up. It has won a variety of awards, including one presented by Kevin Kaiser, a well-known car enthusiast who I have looked up to for a long time. I have built 34 mandolins and 14 guitars over the last 30 years. Byron Berline – one of the best fiddle players in bluegrass – even bought a few of my instruments.

What advice do you have for people starting in this career?

What advice do you have for people starting in this career?

You have to stay healthy and light on your feet, and you should always work hard. It’s all related. The more guitars I build, the better I get at building cockpits or interior parts. Craftsmanship covers a wide range of disciplines and they all benefit from staying motivated and working hard. My grandfather taught me that working hard was the right thing to do, and that working with your hands is an honourable profession. My father taught me to be patient. You must know when to be politically correct, when to be creative and when to apply your experience. Finally, don’t take your work home with you because you need to recharge your batteries.

What has surprised you, and what would you change?

When I started, close to 30 years ago, cabins felt more like buses. Today, our interiors are the highest quality and the customer is the driving force. I would like to see more frequent upgrades, but that’s not always practical. I also want to see a panoramic window before I retire.

This interview was published as part of a larger feature profiling craftspeople in the July 2019 issue of Business Jet Interiors International. Click here to read the full article.