Tray Crow, director of interior design at Gulfstream Aerospace, reveals the current trends he has noticed in business jet interiors

Are there any particular features that are extremely popular at the moment?

Aircraft interiors have, historically, had neutral color palettes, to cater to the resell market. Now, one of the things that we’re seeing quite a lot of is customers making bolder statements with their interiors – opting for a bolder color palette and higher contrasts. Perhaps, they might have a darker carpet and lighter seats for a higher contrast interior. We’re also seeing a lot of personalization through the details – for example, the stitching on the seats.

Is carbon fiber growing in popularity?

We do have customers ask for it on occasion, but it doesn’t seem to be a prevailing trend. I think most of our customers still prefer natural wood veneers to give the space a really warm feeling. Flights are getting longer as aircraft range gets longer. We’re seeing that reflected in individuals wanting a serene environment.

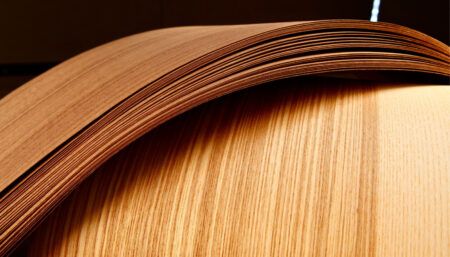

What trends are you noticing in terms of wood veneer species and finishes?

We’re definitely seeing an uptick for matte finishes. However, our customers predominantly prefer high gloss. The other thing we’ve noticed an uptick for is composite, man-made veneer. These tend to be a bit more consistent in color and grain, so they provide a more uniform look in the cabin. It’s not overwhelming the market, but we have seen a rise in uptake.

Is there anything to challenge leather’s dominance as a seating material?

Leather is still the preferred seating material. However, we are seeing more textural changes, maybe nothing very significant, but perhaps heavier textured leathers or alternative finishing. There are metallic finishes that some of our suppliers are offering for leather now. We’re seeing customers interested in that. Some customers are still opting for fabric inserts on seats, for comfort, but by and large, leather still rules when it comes to seating materials.

What trends have you noticed with flooring?

We are seeing different flooring materials – maybe not in the cabin, but certainly in the galley. There is a trend right now for a variety of higher levels of finishing for flooring in the galley and lavatory areas.

We also offer vinyl – these offerings have really grown in the past several years. The range for vinyl used to be very limited, but there are a variety of textures and colors that are emerging now that customers seem to gravitate toward. Vinyl is a user-friendly option, from a functional standpoint. But the stone and wood floors of the future will offer a higher quality aesthetic.

What’s caught your eye in terms of lighting?

Lighting is becoming a major focus in aviation interiors in general, across the market. There is more concerted effort to unify the lighting scheme within the cabin to really set a mood or a tone in the interior. Here, color temperature is incredibly important.

What about window shades and photovoltaic glass?

We don’t currently offer photovoltaic or electronic glass. I think customers like the ease of use offered by a traditional window shade. Also, they ensure total blackout when passengers want to sleep.

Are there any new materials or innovations you would like to look at in more detail?

Natural materials are always the prevailing trend. It’s really about having a comfortable cabin. Wools and cottons are emerging in the lifestyle markets and that doesn’t sound very innovative, but it truly is representative of the marketplace today.

What about materials such as glass and mirror?

We are actively researching anything new within those markets. Glass and mirrored finishes are not something that we currently have in our cabins.

How do you keep track of what your customers want?

We get a lot of feedback from our customer advisory board; it’s very active. We really utilise it as a platform to ensure that our cabin designs are appropriate and meet the needs of our customers. It also keeps us on task with the function of the cabin.

Have you seen any shifts in customer demographics?

The market is always changing. I don’t think we’ve seen a major shift in the demographic of our customers in the past five years.

What technology are you using during the customer specification process?

We’ve just launched a cabin configurator tool, which we use on the G500, G600 and G650. It allows customers to view a multitude of floorplans, and really opens them up to the flexibility of the cabin. It’s an iPad tool that we use to help customers select the configuration of their aircraft. It’s really the launching-off point for everything else. Color and material selections really follow what happens with the configuration.

We also use Design Book for the G650, G600, G500, G450 and G280. It’s an iPad app that helps customers explore colors and materials within the cabin. They’re able to select light, medium and dark veneers and a multitude of carpet patterns, and then incorporate leather and other supporting materials.

Those two tools are really effective in helping derive a design solution that’s going to meet the customer’s needs. What we really enjoy about these apps is that they are mobile. We travel all over the world to work with our customers, although they can also come to one of our sales and design centers, where we can augment that experience with other 3D tools. Our US centers are in Long Beach, California; Dallas, Texas; and Savannah, Georgia. We also have one in London, UK.

This interview was conducted in May 2015