Multifunctionality and sustainable solutions are some of the biggest trends noted by Summer Sun, manager of interior design and programme manager at Flying Colours

What aesthetic trends have you noticed becoming more prevalent recently?

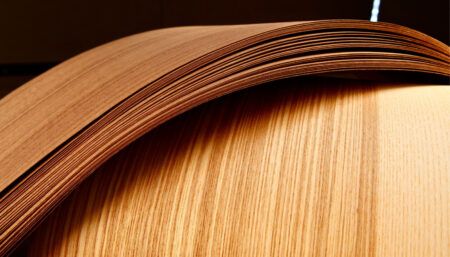

There’s been a general move towards more organic shapes and styles, curves and minimalism. There is also growing demand for renewable and biodegradable bio-based materials and wood flooring. We are receiving more requests to have wooden-style flooring in the entrance and galley areas. This sleek look can add a dramatic contrast to the cabin carpet.

In terms of colours, warm grey has been rising in popularity over the last few years, and you often see it alongside dark brown veneers. It is only a matter of time before we also start seeing cooler greys being used.

With metallic finishes, brushed options are becoming more popular. With weathered, distressed and worn styles in demand, we should soon see more distressed/tarnished metallic finishes incorporated.

With the growing demand for customisation, lighting options will have to branch out from what is typically offered. For example, when lighting is used instead of window blinds, you eliminate the physical material, saving weight and adding new technology.

Carpet design is changing, from being focussed on only the centre aisle to an overall pattern throughout the cabin. Some patterns now move from left to right rather than forward to back, which makes the cabin feel wider. Another design trend we’ve noticed is that airducts are being matched with dado rail materials to make the aircraft corners cleaner. These have traditionally been covered with carpet.

Finally, seat designs have been changing from bulky to sleeker forms. Complementing this is the growth in popularity of two-tone seats, usually with a lighter colour on the inside area and a darker colour on the outside of the seat. This makes the seat feel more open and less confined. The customisation of head and foot rests is also making seats more comfortable, in line with individual preferences. As well as the addition of design elements such as different stitching designs and insert accents, we are seeing more insert accent stripes rather than traditional piping these days.

What new technologies are you being asked to integrate?

Certain aspects of automotive design – including interior lighting, seat design and futuristic controls – have transferred into aircraft design. The trend for two-tone seat designs has been influenced by the automotive sector, along with accent stitching. With automotive accent lighting having advanced a lot in the last few years, I expect the request for custom accent lighting for aircraft is just around the corner. We’ve also been asked to incorporate mood/accent lighting into seats.

Customers are also requesting more touch and rotary dial controls to be integrated into the design rather than the manual switches. For IFE controls they want rotary dials in addition to touchscreens.

We have also noticed an increase in demand for laser printing on materials including leather, vinyl, stone and wood. This is a good resource for incorporating logos, artwork and other graphics.

Another thing we’ve been asked to incorporate is coloured carbon fibre. This material has been growing a lot in popularity, and alternative colours are in high demand. Finally, with the improvement of water transfers and high-end vinyl wraps, we are able to imitate the look of materials such as wood, marble, mirrors and organic textures. This delivers a whole new spectrum of customisation possibilities.

Do you have any other new ideas you’d like to work on?

I would like to come up with new designs for multifunctional furniture, for example seats that convert into beds and chaise chairs, as well as removable privacy walls, and easily convertible divan/bed options. Multifunctional furniture would be very useful, because aircraft have such limited space.

I’d also like to work on incorporating mood lighting into seats and bulkheads; incorporating lights into the headline that could mimic the sky and make the cabin feel less tight; and adding interest to the headliner.

Another idea to develop is removable/changeable inserts for cabinets, to customise the interior, as well as more modular systems that are easy to change and reconfigure to your needs.

Have you noticed any other important trends?

We’ve had requests for clear bulkheads as well as half bulkheads, incorporating more functional design and open-grain veneer. Clear/glass bulkheads could possibly incorporate technology to enable them to darken and lighten as needed. With space at a premium, as well as half bulkheads we’ve had a number of requests for a bulkhead only on one side, which gives a more open feel. In addition, the position of the door in the bulkheads has been changing from a central position to off-centre, which allows the layout to flow in line with the seats.

Open-grain veneer has been getting very popular. You are able to see and feel the texture of the wood grain. In the near future I believe recycled materials will be more prevalent. With the rise of environmental concern and the reduction of the amount of plastic in our oceans it is only a matter of time before recycled plastics make their way into more materials.

What will you be looking out for at NBAA-BACE?

I’ll be looking for alternative cabin flooring options, products with weathered/worn finishes, new interior finishes and materials with fast turnaround times.

This interview was published as part of a larger feature discussing design trends in the October 2019 issue of Business Jet Interiors International. Click here to read the full article.