While real natural materials are particularly luxurious, they are not the only viable options for business jet cabins – and there are many factors involved in the choice, finds Marisa Garcia.

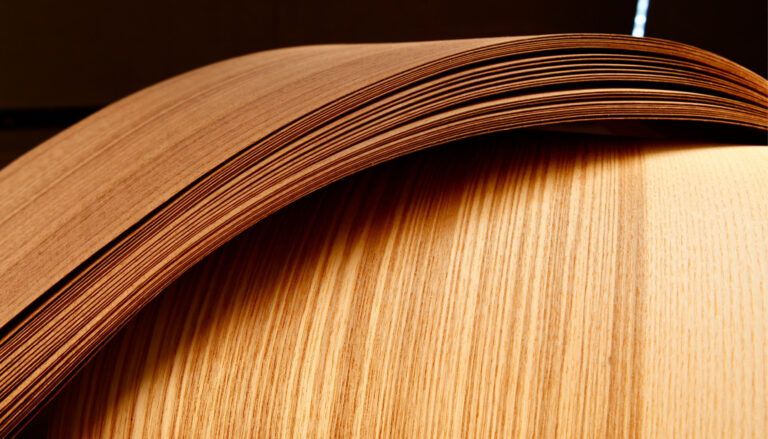

Business jet owners these days have many options beyond traditional wood veneer when it comes to hard surfaces in the cabin. Their choice may factor in not only design preferences, but also service life and maintenance considerations. Manufacturers can simulate the appearance of materials like wood, carbon fibre, and marble using hydrographic and vinyl wraps.

Although Duncan Aviation uses real veneer in many cases, it has been experimenting with simulated finishes for over a decade in its refurbishment projects, providing alternative solutions for veneer and other natural materials. “We combine a lot of the techniques together,” says Nate Klenke, sales manager, modifications. “Within a full shipset of cabinets where we’re using hydrodipping technology, it may not all be applied the same. Some may be applied to another substrate and then applied to a cabinet; some may be directly onto the cabinet.”

Klenke says as the techniques have been refined, the simulated product has become very convincing. “We use automated sprayers so that we apply the same amount of activator to the film before the product gets dipped,” says Klenke. “If you do it by hand, it’s not consistent, you kind of push the product around so you don’t get straight lines on patterns like carbon fibre. We have racks now that will dip product into the tank so that it’s done at a consistent pace and the pattern goes on the way it was intended.”

Installation techniques are another part of making simulated veneer convincing. “If you know what to look for, you can see it’s simulated, but we’ve done some things to even hide that as well,”’ says Klenke. “On a drawer for example, the face may have been dipped completely, and the edges would have had the grain running in one direction. Now we can do it so that the grain runs in the other direction.”

A growing number of Duncan’s projects include some type of simulated finish – often applied to countertops and parts with unique shapes, like drink rails, and in cabinets to a more limited extent. Some natural materials are more straightforward to simulate than others. “Marble and stone are much easier than carbon fibre,” Klenke says.

Repair advantages

One of the main advantages of simulated veneer is the ability to repair damage more easily than natural materials may allow. “Wood veneer is grain-matched across the entire face of a cabinet,” says Klenke. “That doesn’t mean I can just repair that drawer front; I have to do the whole cabinet face. Say that veneer was sourced six years ago from a specific log; I now have to find something that will match to replace the whole face. With a simulated finish, we can go back to the stored image of it, find its location on the cabinet, and re-apply to just that area.”

This ease of repair makes simulated finishes popular with charter operators and others with high aircraft utilisation, Klenke says. While using simulated surfaces to patch a damaged natural surface is theoretically possible, Klenke says simulated veneer can’t fully replicate the complexity and depth of grain of its natural counterpart. “That’s why real product is still so much more luxurious, especially in a wood veneer,” he adds.

Reclaimed veneer

Another option is reclaimed veneer, which Adam White, CEO of Comlux America, explains is being used increasingly, offering a sustainability-focused option. “It’s still wood, but they’re not cutting down a virgin tree,” he says. “It actually gives it quite a bit more character than the traditional approaches.”

Comlux sees less demand for hydrodipping. “We are starting to see some non-organic materials like carbon fibre used in decorative applications, or even for bulkheads for a modern, clean look and feel,” explains White. “It’s not over the top, but it is starting to replace some of the rare species or different types of woods that we use.”

Sylvain Mariat, head of Airbus Corporate Jets Creative Design, says that natural materials are the preferred option: “We have many options depending on the certification of the aircraft; most of the time we can use a real wood. It’s the way we like to do it. We have to select the exact wood designed by the customer, and also the varnish quality; it could be matte, satin or polished very bright.”

Mariat says that sometimes government or military aircraft certification standards are akin to public transportation ones, which can mean real wood doesn’t meet flammability requirements. In such cases, simulated wood is one option. Mariat prefers to go with “more contemporary”, high-quality paint instead, not attempting to mimic wood, but will follow the client’s wishes.

Even when real wood veneer is chosen, there is still the choice of varnish to consider. Mariat has noted a growing trend of customers asking for open-grain wood textures. “Open grain is when you can feel the texture of the wood, it’s not flat,” explains Mariat. “Customers want to make sure that it is not a fake wood.”

Michael Müller, managing director at F/List, says that affluent private jet owners want an experience similar to their living rooms at home: “They don’t see any reason why real, natural wood surfaces, oiled surfaces, are not applicable on their aeroplane.”

F/List has a new development to meet this demand: the transparent, plant-based, F/Lab Natural Oil, doing away with the lacquering process. It was showcased at NBAA-BACE 2024 – along with sustainability-focused materials F/Lab Aenigma Eco, F/Lab Whisper Leather, F/Lab Fresco Décor and F/Lab Linfinium – on a partial PC-24 cabin mockup developed in collaboration with Pilatus.

Triggering demand

André Zimmermann, VP of business aviation at Pilatus, hasn’t seen a lot of demand for sustainable options, but thinks this can result from manufacturers showing the possibilities. “We’re very curious to see what the customer thinks about it,” says Zimmermann. “If you always wait for the customer to ask for something, you’re kind of late. If you can offer it to the customer, say we have an option to the more normal leather and veneers, we have something that is built with a sustainable mindset, so why not take this as an option to the norm? Then I think you trigger a demand.”

Zimmermann is excited about the “many opportunities” in colour and texture offered by the F/List materials incorporated in the mockup. “Let’s see how the market reacts,” he adds.

In terms of F/List’s existing range, Müller says demand continues apace for stone veneer, and the next step is heated stone flooring. “An upcoming demand, which is increasing, is that people who are having the stone floor, want it matched to the countertops and to the work surface,” Müller adds.

Carbon fibre

Another trend is the continued appeal of carbon fibre. “We’re putting a lot of carbon fibre into the aircraft, for accents,” shares Matthew Bergwall, executive director of the Vision Jet product line at Cirrus. “Carbon fibre has been something that we’ve seen as accents and put in our aircraft in 2009, and it’s still something that is very well requested.”

Comlux’s White thinks that the appeal of carbon fibre has lasted longer than perhaps the industry expected. “Some of the different colours and ways that they’re using that material now are quite interesting,” he says. “Whether it’s a fad or not, I don’t know, but it’s a non-organic material. It’s interesting to see it being used.”

While it is a look that can be simulated, ACJ’s Mariat again prefers the real deal. “Sometimes we have a customer who wants to see the real carbon fibre – so same, I don’t like to use fake coloured fibre,” he comments. “When you want to use a real carbon fibre we have/had a partnership with an automotive manufacturer that can apply the fabric of the carbon fibre, with the direction of the fabric perfectly managed, you don’t have any kind of disruption. It’s very difficult to manage, but when it works, it’s very nice. But I think it was more trendy before.”

Natural or not, deciding which hard materials work best in any project is ultimately up to the customer. White of Comlux explains that it is the interior design team’s job to enable the customer to make informed choices by explaining the benefits and limitations of each option. “They hear the customer requests,” he says. “They’re the front line in saying, ‘Well, here’s the drawbacks of doing something like that’ – not that we can’t do it, it might be a question of time and money. They explain the difference between a reclaimed veneer and typical veneer, and even what the coating appliqué is as well. They hear a lot of that, and come back with a more refined product to review.”

This feature was written by Marisa Garcia and first published in the December 2024/January 2025 edition of Business Jet Interiors International. Click here for the full article.