Inspired by aviation’s Golden Age, Jekta is working to bring an amphibious aircraft to market that is designed to solve modern-day problems.

In the drive to make aviation more sustainable, new forms of flight are emerging, such as eVTOLs. Jekta has a different vision – to update something from the past, to meet modern concerns. It is working to develop a zero-emission amphibious aircraft.

The Passenger Hydro Aircraft Zero Emission (PHA-ZE) 100 is intended to offer outstanding flexibility for regional operations, operating from water (rivers, seas and lakes) as well as paved and unpaved runways, with a short take-off and landing feature; and transitioning between these without extra hardware. Other features include reverse thrust; 360° turn capability in water; and blown lift to amplify lift at slow speeds.

Jekta says the vehicle could reach a 13,700ft (4,500m) technical flight altitude; 110kts cruising speed (or 50kts VSO); and fly for one hour with a 30-minute reserve (battery version); handling waves up to 3.9ft (1.2m) high. It would operate with distributed electric propulsion, using battery blocks or hydrogen fuel cells, either producing zero emissions.

For industrial design, Jekta calls on the talents of Max Pinucci, CEO of aviation design studio MBVision, and also an author and aviation professor. He’s worked in aviation for over 20 years, and with seaplanes for about 15 years – and had a long association with key leaders at Jekta before the firm was even formed. He can also draw on his experience as a pilot who had the opportunity to fly the first seaplanes designed by the team.

Pinucci has always been fascinated by aviation’s ‘Golden Age’ in the 1920s and 1930s – when seaplanes and airships were prevalent. From his start with Jekta Pinucci aimed to bring some of the sensibilities of the time to the forefront, for example in terms of beauty and ergonomics. “This plane has a completely different charm, because we are going to fly relatively slow and low,” he says. “This is perfect for regional transportation and luxury. To me luxury is not about gold, it’s about time and experience. You’re going to experience something completely new.”

Pinucci believes the cultural memory of seaplanes will help in the adoption of zero-emission propulsion. “Even if the PHA-ZE 100 is completely different in terms of materials, performance and powerplant, seaplanes are part of our past,” he says. “We didn’t have to do a crazy or over-designed project; we tried to bring the feeling. We’re on the cutting edge of technology, materials, ergonomics and living space, but at the same time, bringing back things from the past.”

Certification framework

Jekta is aiming to certify the aircraft to EASA CS-23 and US FAA FAR-23 standards for fixed-wing passenger aircraft. “It’s kind of a recent certification, and for now, the biggest challenge is that only a few planes have been designed for this category,” says Pinucci. “That means that we have to sometimes invent solutions in terms of design for the category.”

As the PHA-ZE 100 is a non-pressurised aircraft that will fly relatively low altitudes at relatively low speed (compared with jets), the design team have certain freedoms. Firstly, a lot of the normal aviation equipment is unnecessary, giving more space in the cabin and luggage compartment.

Secondly, it allows for bigger windows, a key feature. The team is not concerned about too much light coming in, as there are many possible solutions, from tints to photochromic surfaces.

Pinucci adds a third benefit to flying low – passengers can see what they’re flying over in detail: “You can recognise the place, see the people. It’s a completely different feeling. I think that today, being rich means having these possibilities.”

On the subject of speed, he points out the aircraft has the flexibility to enable more direct flying. “You can land near your yacht, pick up a tender, and travel from your flying boat to your yacht – it gives you a completely different sense of freedom,” he says. “Our plane is intended to give a fantastic experience with a footprint of zero. You can make something really luxurious being respectful at the same time.”

Cabin flexibility

The cabin is spacious enough for passengers to stand up. The modular platform enables pre-designed seats and components – such as a bar or charting table – to be attached to structures hidden in the floor.

The aircraft could be used for everything from multi-leg regional flights to high-end tourism, corporate shuttle, governmental flights, air ambulance service, and more. In May 2024 Jekta unveiled two interior families – the entry-level Traveller (envisaged in 19- or 15-seat versions) and the executive Voyager. Pinucci shares a mix of these two styles is possible, as well as a full VIP offering where owners can create or commission their own completely bespoke interior. A Combi layout is split to leave room for passengers’ motorbikes, kayaks and so on – with the aircraft’s double doors making it easier to bring these on board, Pinucci says.

Windows to the world

As the aircraft will fly relatively low, passengers will be able to use their PEDs’ terrestrial data packages, or the onboard connectivity. OLED screens could be embedded in the headrests in Traveller cabins, and on the tables in the Voyager cabins, but the team is investigating how information could be integrated into the windows.

As well as the expected flight information, Pinucci wants the system to help passengers truly understand what they’re flying over, with information appearing on the windows, as well as perhaps historical photos, AI interactions. “This, to me, is luxury; the fact you can access things that are not normal,” says Pinucci. “Imagine the possibilities for an AI interaction. You can talk with the plane, ask him to tell you a story.”

Definition status

The target service entry is 2030, so decisions on materials and technology are open-ended for now. “Solutions are improving every day,” says Pinucci. “We’re flexible about changing these over the next two years.”

In terms of the aircraft structure, Pinucci shares that Jekta is at the stage of making a 1:1 section mock-up, which it will use in conjunction with virtual/augmented reality to thoroughly understand the space in refining the design. As for the seats and other interior components, he says these are at a stage of “quite high” definition, and the next stage is to create 3D models.

Water features

Water operations bring unique challenges. “We need to always be aware about the impact of humidity, salt, things that normally you don’t consider when you make a plane,” shares Pinucci. “But luckily, we also make boats, so we know where to start. In the past, there were basically no boundaries between aeronautics and the naval field.”

Robustness is also important, to handle the impact of landing on water. Aside from the engineering challenge, “you also have to reduce the number of things in the plane; you have to store everything in the proper way”, explains Pinucci.

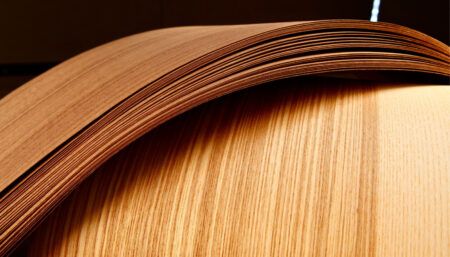

As PHA-ZE 100 is a flying boat, the entrance doors need to be quite high, to avoid water ingress to the cabin. This means designing a ladder that can work both in the water and on the ground. The interior flooring also is reminiscent of a boat deck, with materials to suit. “We’re playing with quite interesting materials, like cork, composites made out of hemp and other materials that are not very common,” shares Pinucci. “Here the problem is to face the certifications, but I’m pretty sure we can start this process talking with the authorities.”

Other features of the aircraft include a toilet and a double door that is split “because when you are flying with 19 passengers, you can’t open both,” says Pinucci. “This kind of plane doesn’t exist today, so we can’t be inspired by others’ solutions.”

This feature was written by Izzy Kington and first published in the September/October 2024 edition of Business Jet Interiors International. Click here for the full version.