Representatives of aircraft OEMs and interior design firms discuss strategies for sustainability

Anne Farken, associate director, sustainability and creative consulting, Designworks, a BMW Group Company

Is sustainable design of growing interest to the market?

Is sustainable design of growing interest to the market?

GenZ can see through greenwashing quickly and expects companies to treat them as equals. Brands that really contribute to society and environment will make a deep connection to the next generation.

What factors matter when trying to make sustainable choices?

Designers need to think about environmental and social responsibility in terms of raw materials, production, transportation, product use, disposal and recycling. This will lead to the adoption

of new business models that measure success in new ways.

Should the industry improve how sustainability is talked about?

A lot of the terminology has no standard definition – but I’m happy to share my understanding. ‘Eco-design’ considers environmental factors in design, while ‘sustainable design’ also includes social aspects. ‘Circular design’ aims to reduce waste and enhance resource efficiency, often utilising strategies like ‘product as a service’ and emphasising reparability and maintenance. ‘Regenerative design’ goes further, considering cultural and societal factors, actively contributing to the regeneration of eco-systems and communities.

Words like ‘sustainability’ and ‘innovation’ have become vague buzzwords. At Designworks, we address sustainability in very specific terms at the start of every project. Together with our partners, we define the purpose of the project, formulate measurable goals and reflect on the questions we want to answer. We call this ‘design for intention’.

How can companies best integrate sustainability into their culture?

Firstly, by embracing that profitability and sustainability are not mutually exclusive. New key performance indicators (KPIs) are evolving to reflect this synergy. Secondly, it’s not enough to make sustainability an agenda item. Integrating external partners and nurturing cross-functional teams enhances the potential for fresh perspectives in future-proofed solutions. It’s equally vital to embed these changes in underlying structures. Thirdly, accept that change is positive! We’re transitioning from an industrial to a knowledge society, where creativity is pivotal for progress. Leveraging designers’ intuition and their expertise in utilising complexity, even within the realm of business strategy, is crucial for driving the transformation towards a future we all want to live in.

Jay Beever, VP, Embraer Design Operations

How have your design ideas progressed since the Praeterra concept?

How have your design ideas progressed since the Praeterra concept?

We’ve introduced sustainable recycled and upcycled materials into our new product development pipeline, so down the line we could have sustainability collections that people can pull from. For example, we’re looking at 3D-printing titanium for interior trim components, using leftover material from the production process in Brazil. I have sample parts in my office of our Phenom cupholder area, 3D-printed in titanium with a beautiful bead-blasted satin finish. It’s not plated, it’s made from scrap titanium dust.

Praeterra had the Mokume-gane, made from folded-up metals, created into a billet. It didn’t need to be plated, because the grain work was the beauty.

What new innovations have caught your eye?

For instance, at EBACE I met with Paolo Foglizzo of Foglizzo Leather, which takes scrap leather, mixes it into a fibre mush, and creates a new leather sheet material, a composite with 15% polyester. I looked at it, smelled it; it’s leather. I’m absolutely thrilled with it. There’s limitations on colour right now, but that’ll expand.

Suppliers are also sourcing hides from farms that raise cattle for food, which would otherwise be thrown away. And they can pick cattle that have been fed seaweed. Including seaweed in feed reduces a cow’s methane output dramatically. There’s a long chain of detail that goes into a material’s carbon footprint.

Natalie Rodríguez, principal, Natalie Rodríguez Luxury Design

Is sustainable design of growing interest to clients?

There’s definitely been an increase in demand over the last few years. On a recent project the client took great interest in the undyed/natural heather dye carpets Kalogridis unveiled at NBAA-BACE 2022. This customer also didn’t want to use materials with PFA substances – synthetic chemicals resistant to heat, grease, oil and water, and also resistant to degradation in the environment. We double checked with suppliers that PFAs weren’t used in the production of their materials or FR treatments.

What factors matter when trying to make sustainable choices?

My favourite factors to consider are positive environmental impact as well as anything that isn’t artificial, but rather, naturally sourced. Customers are also a driving factor – some requests might include all natural, plant-based materials, without any plastics or animal by-products, while some request to have seat leather, but to make sure everything is sustainably sourced and produced responsibly.

What are the challenges to overcome to make more progress?

There might be more hesitation to incorporate new ideas and products that are sustainable simply because they haven’t been used many times before. There might be questions regarding how long certain materials will hold up over time, and how colours from naturally sourced products really turn out in production since there is less control in colour variances or lack of a dye lot.

What other solutions would you like to see developed by suppliers?

I’m loving the direction suppliers are currently moving in – utilising resources found in our natural environment through new plant-based and recyclable materials, as well as natural dyes for colour.

It would be wonderful to see more suppliers come out with their own sustainability lines to provide a variety of options.

There are many beautiful sustainable materials that have been developed in other industries that would be great to use in aviation applications. It would be wonderful for suppliers to invest in having any new and innovative materials tested for applicable burn and/or sliding friction and have the information readily available on the label and their website catalogue. This way aviation interior designers can select their materials with the utmost assurance. This would especially be applicable to suppliers looking to break into aviation, as those that are already in the industry are more likely to test/certify anything new prior to offering these to designers.

Tray Crow, director, interior design, Gulfstream

Is sustainable design of growing interest to clients?

Is sustainable design of growing interest to clients?

Yes – certainly more so now than perhaps 10 years ago. It’s part of how we operate. The new galley on the G700 has a dual-zone trash compartment for example. That’s something we added so that flight attendants can separate recyclables to waste. Even in building aircraft, it’s always been about efficiency, and how we provide more for less.

What are some of your sustainability efforts when it comes to materials?

With our seat leather, all our patterns for the seats are digitised now. Everything’s cut on a Gerber cutter so we maximise the use of every hide. Specifying leather on high-wear surfaces is important because it’s a

durable material – it lasts five times longer than most soft goods. Leather is a by-product of the meat industry and we’re diverting that from landfill. Any waste that we do have is donated either to charities or schools. Some of our waste leather has been turned into soccer balls for schools and communities in need.

Everything that goes into our carpet is natural, down to the latex backing and the jute structure that provides the canvas. The tufting is either silk or wool, both rapidly renewable resources. One of our suppliers carries the Greenguard certification, so that’s available to our customers as well.

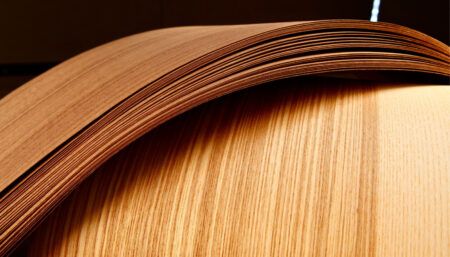

About 40% of the veneer we specify is composite veneer that comes from rapidly renewable resources. Veneer maximises yield anyway, because it consists of thin sheets applied to a substrate. We also focus on lightweight elements such as honeycomb materials.

How would you like to see the wider industry respond?

Innovation is a shared responsibility for the whole industry. With our suppliers, how they’re bringing new products to market, and working on sustainability within their own processes – bringing that to the forefront is important.

Judy Miller, allied ASID, Judy Miller Interior Design

Is sustainable design of growing interest to clients?

Is sustainable design of growing interest to clients?

Wellness continues to be of interest to clients and the A&D industry, driving vendors to go green.

Should the industry improve how sustainability information is presented?

OEMs would benefit by being more transparent with their sustainable initiatives and practices in their advertising. They could promote how they benefit customer wellness and are lowering their environmental impact. Sustainable alternative fuel efforts are great, but there’s so much about interiors that could be shared as well.

Are there any sustainability-focused ideas that have caught your eye recently?

I’ve been very impressed with soft goods suppliers moving more and more into sustainable products.

Tapis is a standout.

How else might the industry make progress?

I’d like to see OEMs and refurbishment centres using more sustainable/green substrates, foams and

adhesives, as well as water-based paints for interior and exterior paint applications. I’d also like to see

materials recycled whenever possible when removed from aircraft interiors, especially in refurbishments,

much like how clients are recycling kitchen appliances, and donating kitchen cabinets and furniture to places such as Habitat for Humanity ReStore.

Sylvain Mariat, head of creative design and concepts, Airbus Corporate Jets

Was sustainability a design factor for the first ACJ TwoTwenty completion?

Yes certainly; at the beginning of the project, we agreed that most of the material suppliers would be located not far away from Comlux’s completion facility in Indianapolis, USA, to minimise carbon footprint. We have also focused on the origin of the wood veneer used for the interior fittings and we decided to use wood with the Forest Stewardship Council (FSC) label.

In what other ways have you addressed sustainability?

It’s not new for us to address sustainability with materials. For example, we work with a French partner on a solvent-free paint that we propose to our customers.

We can also talk about leather. We recommend vegetable tanning to our customers instead of chemical tanning. For carpets we use wool and silk – natural materials rather than synthetic materials.

Beyond the materials used, we encourage our suppliers to propose cabin designs with optimised weight, mainly through design conception or the use of innovative lightweight composite.

How do you design a cabin to have a long life?

A sustainable cabin means also designing to avoid having to replace large parts to perform small repairs. For example, we make partitions from a combination of parts so that if there is a scratch, we only need to remove and repair one small part. I also like using paint on cabinetry because it can contribute to saving weight; it is easier to maintain; and to extend the component’s life.

How important is recyclability?

Our approach to environmental responsibility doesn’t end at the design stage. During manufacturing, after delivery and even at the end of an aircraft’s service life, we continue to search for ways to reduce the environmental footprint of our aircraft. Airbus and Tarmac Aerosave have established a proven method for decommissioning, dismantling and recycling the entire Airbus aircraft product range in an environmentally responsible way. We are able to recycle more than 90% of an aircraft.

Mindy Huang, sales engineering, Bombardier

Is there a lot of interest in sustainability from clients?

A lot. Sustainability is a huge movement. A lot of clients think it important to reduce their footprint, so we have a whole catalogue of options and take a scientific approach to studying CO2 impact and water scarcity. An example is Eucalyptus veneer. Eucalyptus grows very fast and doesn’t need to be uprooted to harvest; you can cut it at the trunk and it’ll regrow. It’s a very sustainable material.

What is the aim with your environmental product declarations (EPDs)?

We have a sustainability team that produces the EPDs. That studies every single part that goes on an aircraft, so we’re very transparent about the impact of the product’s lifecycle on the environment. The scientific assessment that underpins the EPD helps Bombardier to optimise the design of its products according to sustainable criteria.

Is there anything else you wanted to share?

Bombardier’s ESG plan includes a commitment to invest over 50% of our R&D towards greener aircraft by 2025.

This feature was first published in the September/October 2023 edition of Business Jet Interiors International.