Ron Larabie, owner and president at JetSet Interiors, details how new seats and soft goods transformed a GIV

What work did you perform on this project?

What work did you perform on this project?

The work scope consisted of a full soft goods refurbishment to brighten up and modernize the cabin and lavatory areas. When the aircraft arrived all the seats, the divan and the carpet were a dark brown color. Our task was to take the aircraft from having a dark interior to the bright and airy one that the client was looking for.

All the cabin seats were redesigned and reupholstered using an off-white Aeristo leather. We are known for a special type of aircraft seating, our Signature Seating. We don’t just change out the color and material, we change the design and function of the seat, without affecting the original TSO of the seat manufacturer. This aircraft features a light model of our Signature Seat for the GIV. The design was taken further with a double diamond stitch pattern using a darker thread that was added to the lower lumbar and seat cushion areas. The lower seat shroud was updated by removing the heavier base and replacing it with JSI’s custom one-piece shroud – a Tyvek base covered in matching leather. All restraints were re-webbed in a matching color and the belt and seat hardware was re-plated in a gold finish to complete the transformation.

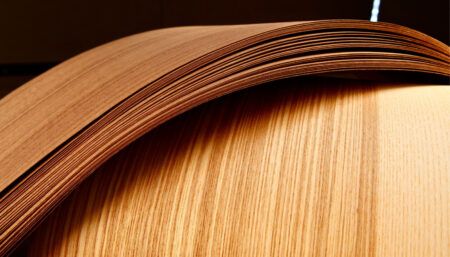

The three-place divan was recovered in a light Chenillo fabric, selected as a complementary color to the leather used for the seats. Again, all restraints were re-webbed in a matching color and the belt hardware and cup holders were re-plated. A contrasting Chenillo fabric, slightly darker than that used for the divan, was selected for the lower dado panels.

To dress up the cabin and lavatory areas and provide a fresh look, Ultraleather in White Dove was selected to recover the headliners, PSUs, sidewalls and valence panels. Finally, a custom-made three-color carpet was selected to complement the new color scheme for the seats, divan and panels.

All seat work was completed at our seat shop in Dallas, Texas, managed by James Mason, the seat shop upholstery manager. The 29,000ft² location is our newest facility. All other work was completed at location in Van Nuys, California, and managed by Alan King.

Were any new materials, technologies or processes used?

While sometimes we do use new materials and complete unique projects, with the time constraints on this job we employed materials and processes we were familiar with.

What was the most challenging aspect? Were there any parts that were particularly complicated to certify?

What was the most challenging aspect? Were there any parts that were particularly complicated to certify?

This refurbishment followed all industry and FAA standard policies and certifications and was completed and signed off under JetSet’s Part 145 certification. Additionally, the material and leather selections had to pass flammability testing.

How long did the refurbishment take?

The entire project was completed in 27 days. This type of refurbishment typically takes five to six weeks, however the customer had a limited downtime and wanted the aircraft completed before the Christmas holidays.

How did you minimize cost and downtime for the client?

A modernized color board – using light earth, white and off-white colors – was designed by James. He carefully selected readily available material/leather options that he knew would help transform the aircraft interior, meet the customer’s expectations, and stay in budget. James and Alan also worked closely with our carpet vendor to prepare a competitive quote for the customized carpet requested. Besides the carpet, avoiding custom materials and leathers and selecting readily available options allowed us to keep the cost down and stay in-line with the customer’s downtime.

Additionally, a full seat rendering was completed and approved by the customer before work began, to ensure we could begin work quickly with customer approval.

What is your favorite detail?

What is your favorite detail?

What really transformed this aircraft were the seats and color choices. The seats fit nicely in this aircraft and give it a sleeker and more upscale appearance. The white leather with the diamond stitching and gold plating add to the feel of modern luxury. We always love the opportunity to complete a Signature Seat because it goes a step further than just a reupholstering job. We create a totally new design that fits with what customers are looking for. What’s also great is what you can’t see – the improvements to the overall function of the seat. The customer has options including USB outlets, pockets within the seat and more sitting room. Overall, we love to know that we are putting in a great seat that looks great, but also provides more functionality.

Can you share any other projects you have lined up?

We’re working on a complete Falcon 900 refurbishment in our Dallas shop and should finish that up in the next few days. We’re also doing various pieces for a Learjet 60, and preparing for another full GV job in Van Nuys.