Flying Colours Corp’s vice president of design, Kate Ahrens, discusses a Bombardier Global Express refurbishment – the company’s first project to include pre-engineered components from Inairvation.

Flying Colours Corp is embarking on the refurbishment of a Bombardier Global Express, the company’s first project to include pre-engineered components from Inairvation, a joint venture between Lufthansa Technik and F/List. Kate Ahrens, vice president of design at Flying Colours Corp, discusses the initiation of the project and what it means to combine a customized cabin with pre-engineered items.

Flying Colours Corp is embarking on the refurbishment of a Bombardier Global Express, the company’s first project to include pre-engineered components from Inairvation, a joint venture between Lufthansa Technik and F/List. Kate Ahrens, vice president of design at Flying Colours Corp, discusses the initiation of the project and what it means to combine a customized cabin with pre-engineered items.

What project milestones have been reached so far?

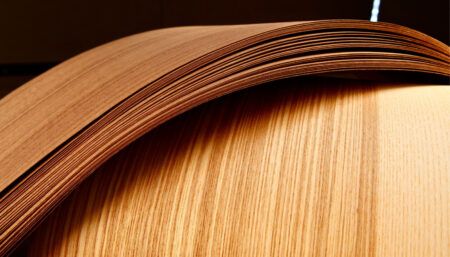

The design was finalized and approved by the client in July 2016, so the project has now entered the engineering phase. Some of the materials we will be using are very new, including a carbon fiber/fiberglass twill blend. Our team has conducted a lot of research and testing to make sure we understand the true capability of this material. It will be used to re-cover all major monuments, tables, sideledges and lavatory vanities.

How have you been working with the client?

We went through three major design sessions with the client. Our aviation team already has a great working relationship with the client, we have worked with him on various projects over the past decade.

For this project we’ve made a point of meeting with him on a number of occasions to make sure we have the details just right. We also stay in constant touch via phone and email, although he trusts us once we have agreed the design to move ahead with the project.

What techniques/technologies have you used to give the client a feel for the design as it has evolved?

We used 3ds Max to produce realistic concepts and renderings. This is a great way for the client to have confidence in giving final approval. All the custom materials look great on a sample board but it is not the same as seeing how the cabin will actually look. The 3D renderings really enable us to bring his vision and our suggestions to life.

What are the client’s priorities and wishes, in terms of the cabin components and aesthetics?

The client requested an elegant, but comfortable, stylish cabin interior using a cream and green palette. We selected an array of beautiful leathers from Townsend Leather for the seat design, which kept with our overall theme of comfortable elegance. One of my favorites of all the various olive green leathers we recommended is Aniline Gaufrage, an embossed and hand-rubbed cowhide.

Which elements will be Inairvation components?

The sideledges, cabin IFE/CMS upgrade, stone granite countertops and stone flooring are all Inairvation components. The sideledges are a uniquely customized component and integrate Lufthansa Technik’s nice IFE/CMS. We have installed the F/List’s stone granite countertops and flooring in previous Global projects so we are familiar with these products. The client also really likes them, having used them on previous aircraft.

What are the benefits of the Inairvation approach?

It is a pre-engineered package and has been carefully designed to make sure it is tested properly and will work with all Global 6000 floorplans. This means the client will benefit from incorporating an off-the-shelf solution that has already been through rigorous design, testing and development; he doesn’t have to pay for the process again.

However, the interior is designed to his specification too; it saves him time and budget yet he still gets his own customized look. As this is the first implementation we have had a number of design sessions with him to ensure all expectations are met.

Has the normal design process changed for you?

The design process is the same as normal, however we have experienced more changes in communication. Inairvation’s approach has broadened the scope of our teamwork as we communicate weekly with the Inairvation team. Knowing the key team members at both Lufthansa Technik and F/List from previous projects has allowed for a seamless transition as we incorporate the pre-engineered components within the individual cabin design.

What other elements are included?

We are installing new B/E Aerospace seat frames and the lighting is being upgraded to B/E Aerospace LED lighting, including Quasar colored LED mood lighting. To improve cabin connectivity, we are installing a complete new Gogo ATG 5000 high-speed data system. It is important for the client to be well connected.

Externally the paint design is truly customized. We are incorporating a carbon fiber look on the exterior, something very new. There will also be a honeycomb design on certain exterior surfaces. This will give the aircraft real ramp presence.

Have any new materials or components been specified?

We will be using a carbon fiber/brown fiberglass twill accented by an ebony hardwood for all the veneered surfaces. This is a unique look and will complement the interior materials nicely. We are also using Hermes and Kravet Couture fabrics to add refined details.

Which aspects will be the most challenging to realize?

The carbon fiber/fiberglass twill will most likely be the part that challenges our team the most. As it is a new material for us, we have spent many hours researching how it behaves and how we handle it. We have already started production plans and drawings and have undergone a lot of testing so we are confident that we can fulfill the design specification.

What is your favorite detail?

There are so many to choose from! I have been honored thus far to be a part of such an innovative and sophisticated design. The sideledges will be one of the top features in this interior. The seats have been fun to work on, as new B/E seat frames have been designed for overall comfort and will be covered with a variety of hand-tipped leather and outlined by metallic custom green piping. The bold black granite countertops contrasting with the crème granite flooring will be a stunning statement at the entrance. But, the carbon fiber/fiberglass twill, accented by the satin copper rose gold metal finishes, is my favorite detail in this luxurious interior.