Peter Landquist reveals how CTT’s humidification system works in big iron aircraft, and what the company has planned for smaller jets

How does your humidification technology work?

How does your humidification technology work?

Cabin humidity can be as low as 3-5% – lower even than in Death Valley, California, – but the Cair system brings it up to around 20-25%. The system has been in service for more than a decade, and has been installed on nearly 100 long-range executive jets, operating worldwide. It is used in the cabin, flight deck and crew rest areas.

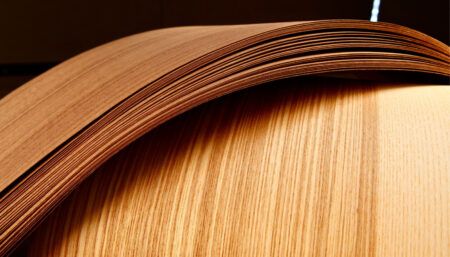

Cair is based on evaporative cooling technology. A special pad made from honeycomb glass fiber is housed in a box placed in the supply line for the zone that needs to be humidified. Water is sprayed over the pad for about two seconds every minute and then dry air goes through the pad, evaporating the water.

The principle was invented by Munters. We redesigned their concept to enable its use in aircraft. Their humidifiers are bigger and they flood the pad with water, which we can’t do in an aircraft, because it would use a lot of water.

Our unit can be activated by an external altitude meter or connected to the aircraft’s system. It’s fully automatic, although in VIP aircraft the VIP can play with the humidification level between 15% and 25%.

What safeguards are there to prevent water leakage and the build-up of bacteria?

The system limits air velocity through the pad, so there is no risk that water droplets can leave it. Trim air is added when necessary to maintain the correct air temperature.

There is a water shut-off valve; a pulse valve to push out the correct amount of water; and a bypass valve that directs the water to either the pad or the drain. When the system is deactivated, these valves open and close a number of times to ensure there is no standing water in the tubing.

The system switches off completely as the aircraft begins its descent, at the same altitude as it is switched on. It is usually about 20 minutes before the aircraft is parked, during which time only air goes through the pad, so it is completely dry upon parking.

Cair installations also include the Zonal Drying system, which reduces condensation by about 75-80%. Air is filtered into an absorption rotor rotating around 11 laps per hour. The rotor is a glass fiber honeycomb structure that is completely impregnated with silica gel crystals that can absorb moisture. To avoid the rotor getting saturated, 20% of the incoming air is heated beforehand to dry the silica gel so it can be released. This system works all the time the aircraft is powered. If the dehumidifying system fails, the humidification system is deactivated.

Will you adapt the system for aircraft smaller than Airbus and Boeing types?

Will you adapt the system for aircraft smaller than Airbus and Boeing types?

We are talking to business jet OEMs, and there is an interest, because those aircraft are absolutely bone dry. The challenge in these aircraft is the tight space envelope, so the only thing that we can do, and what we have tested, is to install a slimmer, tube-shaped humidifier where the pad is encased by the tubing, and the valves and other things are in another location.

We would have to change the drying system as well, but we already have a design created for custom Bombardier CRJ200 installations. We are sure we can do that, and we’re working on our humidifier concept.

What size would the tube be?

The tube would be maybe 250/300mm in diameter, and then for the length, we would work with whatever space was available. We could offer the same basic design with some options for inlet and outlet size.

Where could the tube humidifier be installed?

The air flow volume is still quite high in these aircraft, because there is a high rate of air exchange every hour, so it would have to be fitted below the floor – or in the cargo bay, but the problem then would be routing the ducting.