Wolfgang Lindner – head of the upholstery shop at 328 Support Services (328SSG) – shares the tricks of the trade

How did you get into the upholstery business?

How did you get into the upholstery business?

It has been a family business for more than 100 years, so you can say it is in my blood. Sattlerei Lindner opened in 1911 and those were the days when saddleries did all manner of leather and cloth work, it wasn’t compartmentalised like the industry is these days.

When did you move into the business jet market?

I was offered the opportunity to build up a new upholstery shop at 328SSG two and a half years ago. Moving from ground-based to flying upholstery was obviously a draw and has been a refreshing challenge.

How does business jet upholstery differ from other types?

The biggest difference is the more stringent safety regulations in aviation. For example, one must not use nails or staples, and burn tests are required to prove that all materials and material combinations are not instantly flammable. There are also air pressure issues to consider and functional requirements, with various grades of material available for certain g forces or rubs per minute.

How long did it take you to master the craft?

I am still learning! My grandfather always said that you never stop learning and if anyone thinks they know it all, that is when they will make a mistake.

Are different skills needed for various types of seating and materials?

Are different skills needed for various types of seating and materials?

The skills are the same but there are complications with larger surface areas. For example, one might select a different material for a divan, to prevent creasing, than one would choose for a VIP seat. Some designers avoid all leather on seats to avoid slipping. One should also consider the use and wear. For example, pilot seats must use the best material to accommodate hard wear and tear; and on charter aircraft the armrest areas are the first to become grubby.

What layers go into a business jet seat?

A typical VIP seat has foam layers built up on the metal frame. A rule of thumb is that it should be possible to assemble all parts with some glue, but no tacks, nails or staples. All aircraft interior components have to be burn tested as part of the certification. It is important to test mixed materials because sometimes putting two fireproof materials together creates a different dynamic.

What are your favourite materials to work with?

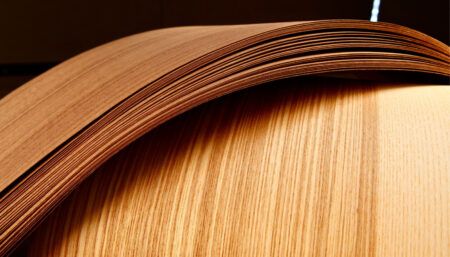

I personally like to work with leather because it is a natural product. Each hide is unique with colour changes, different strengths, perhaps natural anomalies that one must consider. This is why there are always surprises and each item brings its own challenges.

How closely do you work with other departments?

A saddler works closely with the designer – from providing material samples to matching a concept with various stitches, or suggesting methods to turn the corners. Here, the saddler might make a suggestion on how to make something in practice that does not work on paper. Other considerations are how the fabric interacts with passengers. For example, a red wool cloth might rub off on white trousers, or jeans could colour a white seat leather. We also have a good working relationship with the various interior shops and installation team at our one-stop shop.

How long does a seat take to upholster?

How long does a seat take to upholster?

A VIP seat takes longer to design and complete than an airliner seat. We normally work in pairs or in teams of three.

What tools do you use?

One uses specialist leather tools such as the half-moon and eel knife, as well as sewing machines, foam-cutter and leather splitting machines.

How do you bring out the best from the material?

One must optimise the cut and use a good template. Looking specifically at leather, you view each hide and choose parts to use based on their quality and what area they will cover. The best and strongest part is the croupon, or back, and you would use this for seat and back areas. Hidden areas would use the poorer parts such as the belly, where you retain the colour but the quality is not so important. The more calves a cow has had, the looser the fibre texture becomes.

Have you noticed any trends?

For a while there was the laissez-faire style, but this is not what I would choose for creaseless VIP seats! Now leather is in again, especially in the car industry. Here fake leather is in vogue, where even an expert has a problem telling the difference. Colour choices also change with time, with neutral colours most used in charter aircraft. My personal preference is for natural colours, but the customer is always king! At 328SSG we offer clients whatever they want on their new or remarketed aircraft.

What has been your most challenging project?

That would be my first aircraft project with our very exacting designer. It is not only seats that we work on, but all upholstery, from floor, wall and ceiling coverings to curtains, window blinds and cushions. That is why good teamwork is so important when working alongside the cabinetmakers, maintenance staff, certifying engineers, avionics engineers – there are so many points of interaction when installing an aircraft interior.