Lufthansa Technik is pooling its expertise in additive manufacturing (AM, also known as 3D printing) in a dedicated AM Center.

“The new AM Center will serve as a collaborative hub where the experience and skills that Lufthansa Technik has gained in AM can be bundled and further expanded,” said Dr Aenne Koester, head of the AM Center. “The aim is to increase the degree of maturity of the technologies and to develop products that are suitable for production.”

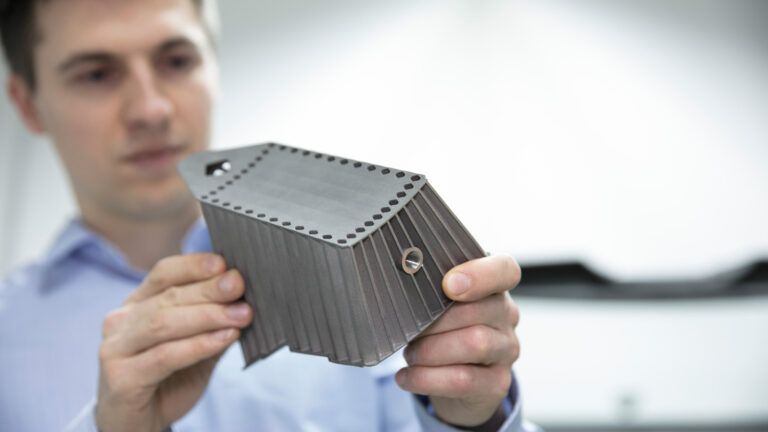

The company says AM grants “unrivalled” freedom in designing parts, and enables parts to be made very quickly – making it particularly useful for prototypes or one-off parts. The technology also has great scope for weight saving.

Lufthansa Technik experts are teaming with AM specialists from various industry partners and research institutions to further the introduction of this technology in the highly regulated aircraft sector.

For example, the company is working with Oerlikon AM regarding process repeatability, to support industrialization and certification. The results of this work will also be shared with industry bodies to aid efforts to define standards for the qualification/approval of components for aircraft.