Ruag MRO International has added a combined painting and drying shop for aircraft components at its aircraft painting facility in Oberpfaffenhofen, near Munich, Germany. The company says the investment will ensure the highest quality and reduced throughput times. The paint shop is now operational following a two-week test phase in June 2020.

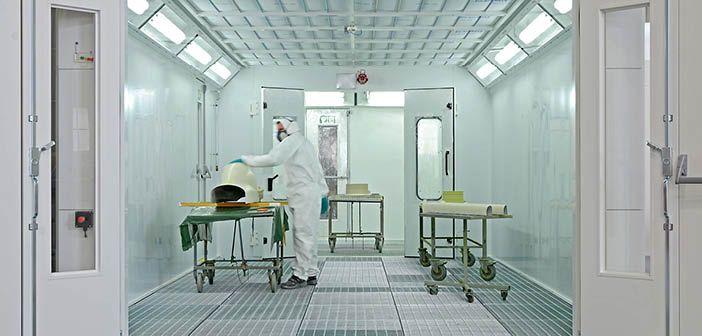

The shop consists of two adjacent booths – one for paint spraying and one for drying. There is space to paint large aircraft components including elevators and rudders, flaps and cabin components. “The new facility allows us to carry out even the most demanding of paint jobs to the highest quality,” said Stefan Schulz, team leader at the paint shop.

The closed arrangement of the two booths enables direct transition from the painting to the drying process, which the company says eliminates the risk of contamination and saves time. “While one component is drying in the second booth, we can get on with painting the next component in the first booth,” said Schulz.

The company added that the paint shop exceeds requirements for environmental protection, energy consumption and occupational safety.