The German Federal Ministry of Education and Research (BMBF) has granted around €6.5m to fund research spearheaded by the Technical University of Munich (TUM) into developing carbon fibres from algae oil. It is hoped the production of this material would extract more carbon dioxide from the atmosphere than it releases.

The Green Carbon project aims to develop manufacturing processes for polymers and carbon-based lightweight construction materials based on algae, which could be utilised in the aviation and automotive industries, for example.

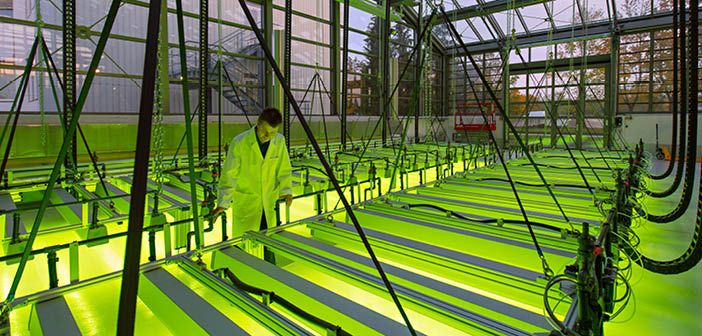

![]() Due to their fast growth, microalgae like those cultivated at TUM’s technical algae centre can actively store the greenhouse gas CO2 in the form of biomass. CO2 is mainly bound in sugars and algae oil. TUM says these can be used in chemical and biotechnological processes to produce precursors for a variety of industrial processes.

Due to their fast growth, microalgae like those cultivated at TUM’s technical algae centre can actively store the greenhouse gas CO2 in the form of biomass. CO2 is mainly bound in sugars and algae oil. TUM says these can be used in chemical and biotechnological processes to produce precursors for a variety of industrial processes.

For example, oil-forming yeasts produce yeast oil from the algae sugars, which is a feedstock for plastics. Furthermore, enzymes can split the yeast oil into glycerine and free fatty acids. The free fatty acids are precursors for products like additives for lubricants, while the glycerine can be turned into carbon fibres.

As part of the project, the plastics will be combined with the carbon fibres to produce composite materials. “The carbon fibres produced from algae are absolutely identical to the fibres currently in use in the industry,” said project lead Thomas Brück, professor for synthetic biotechnology at TUM. “Therefore, they can be used for all standard processes in aviation and automotive production.”

Furthermore, carbon fibres and hard rock can be used in a process defined by industrial partner TechnoCarbon Technologies to produce construction materials.