AkzoNobel Aerospace Coatings plans to launch a virtual reality (VR) training technology for aircraft painting at NBAA-BACE. Customers are invited to test the technology for themselves at the show, to be held on 18-20 October in Orlando, Florida.

AkzoNobel has invested in a technology that mimics a customer’s production environment and multiple coating systems to train teams virtually. The VR-based system, developed with technology specialists Virtual Paint Products, has been successfully trialled at AkzoNobel’s training centre in Troy, Michigan, and several portable units have since been designed for use at a customer’s own premises.

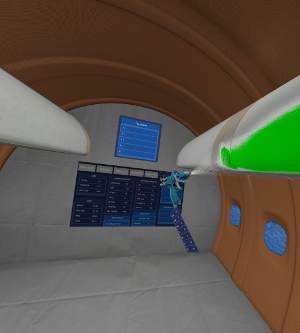

The VR headset immerses the trainee in a virtual paint booth, complete with anything from aircraft parts to larger-scale assemblies to the production floor itself. The system can be programmed with various paint specifications, such as the thickness of the coating required, and as the operator uses the spray gun, they can see whether too much or too little paint is used and look for inconsistencies in the way the coating is being applied.

All the while, the operator’s core skills are measured, from setting up the spraying session to the distance, angle and speed at which the gun is used. The feedback is immediate, so trainees can react quickly and change their technique to become more consistent. It will show where runs and sags occur, or where the wet film thickness is not sufficient or the coverage inadequate to deliver a smooth finish. It also helps them avoid common problems such as paint overlap.

Jeremiah Treloar, chief executive of Virtual Paint Products, said the new system is suited to all levels of training requirements: “The training is not only useful for onboarding new apprentices, but it is also great for teaching advanced skills to more experienced operators. They can practice spraying more challenging parts with rivets, awkward corners, and curves, and in a moving production line. It effectively enables the painter to ‘walk’ the part before spraying wet material on it, and in doing so, it helps reduce the likelihood of defects. It also helps experienced painters to teach new painters techniques on difficult parts or assemblies.”

“If an apprentice or experienced trainee is struggling to understand how to improve their technique, the coach can replay a video of the session and talk them through it,” Treloar continued. “Additional training tools and videos incorporated into the system also improve the training quality and, ultimately, the quality of the workforce. Trainees using the system are fully certified to aircraft industry standards.”

Matthew Amick, global technical services manager at AkzoNobel Aerospace Coatings, said the integration of VR into its training regime is an exciting development: “It reflects the organisation’s commitment to innovation, sustainability and partnerships, supporting our customers with meaningful, practical help.”

“Typically, when a customer asks for training, we have to provide significant quantities of paint, much of which is wasted,” added Amick. “By effectively moving the spray booth into the classroom, we completely eliminate waste, reduce costs and unnecessary shipping, and prevent volatile organic compounds [VOCs] from being released. There are also no costs associated with cleaning the spray guns, or the additional VOCs releases from the solvents required, or in providing the panels needed for wet paint training. It’s a ‘win-win’ for all involved.”