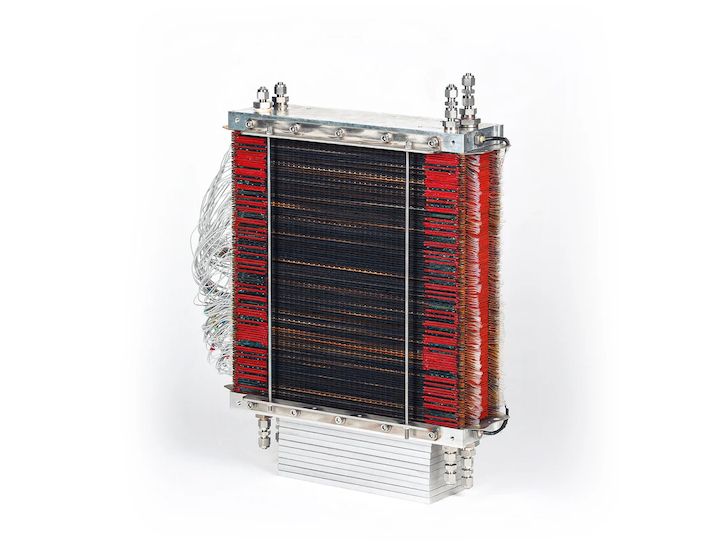

ZeroAvia announced it has achieved “record-breaking performance” in testing of its High Temperature Proton Exchange Membrane (HTPEM) systems. Early testing of the pressurised 20kW HTPEM stack power module in ZeroAvia’s UK R&D location has demonstrated 2.5kW/kg specific power at the cell level, which the company said paved the way for 3+ kW/kg system level densities in the next 24 months.

The company shared that developing fuel cell technology for aviation is critical to enable true zero-emission commercial flight, and for energy-intensive applications – like large fixed-wing aircraft and rotorcraft – it is necessary to increase the temperature and pressure within fuel cell stacks to have a commercially viable product. It added that increased temperature and pressure allows for air cooling, reduces cooling drag, simplifies the system, and ultimately enables more demanding applications.

ZeroAvia said its team has made breakthroughs by delivering a pressurised HTPEM system; conductive coatings that enable the use of aluminium bipolar plates in highly aggressive HTPEM environments; and a novel approach to advanced membrane electrode assembly (MEA).

ZeroAvia’s proprietary technology has been developed over the past three years as part of a concentrated effort to build an in-house portfolio of critical technologies for fuel cell aviation. The company said further R&D will deliver over 3kW/kg fuel cell system specific power, to enable a step change in performance relative to the traditional fuel cell technologies, making fuel cell propulsion commercially viable for large aircraft. Specifically, the HTPEM systems will be prime candidates to support ZeroAvia’s ZA2000 powertrain for 40-80-seat aircraft, as well as a range of rotorcraft and eVTOL applications. The company said this next generation of fuel cells could also be sufficient to enable electric propulsion systems for 100+ seat single-aisle turbofan aircraft such as the Boeing 737 and Airbus A320.

The components used in the ZeroAvia system have been validated through third-party independent testing at several independent labs, including a US Department of Energy national lab. ZeroAvia said the testing confirms the potential for HTPEM systems to accelerate the development of large hydrogen-electric powertrains for large aircraft.

ZeroAvia’s recent first flight of a 19-seat aircraft used Low Temperature PEM (LTPEM) fuel cell systems. The company said that today’s LTPEM systems work well for the sub-megawatt scale of these smaller aircraft, but the lower stack core temperatures make it harder to remove heat from the larger systems. HTPEM technology eliminates a number of components from the fuel cell system and is designed to reduce cooling drag, enabling commercially relevant payload and range.

“Hydrogen fuel cell propulsion is the most environmental and economical alternative to existing engines, and HTPEM is the most promising route to delivering these benefits into large aircraft categories,” said Val Miftakhov, CEO of ZeroAvia. “I am confident that what we are demonstrating now is the core building block to delivering zero-emission flight for all categories of aircraft in the long-term.”

ZeroAvia’s development of the HTPEM systems is in part supported by the HyFlyer II project, backed by the UK government via the Aerospace Technology Institute (ATI).